Corporate Sustainability

Environment

Compared with new materials, it can reduce carbon emissions

The extrusion production line fully uses recycled materials, which can reduce carbon emissions by more than 70% compared to virgin materials.

Injection production line using recycled plastic materials

The injection production line has begun to use recycled plastic materials, to realize circular economy.

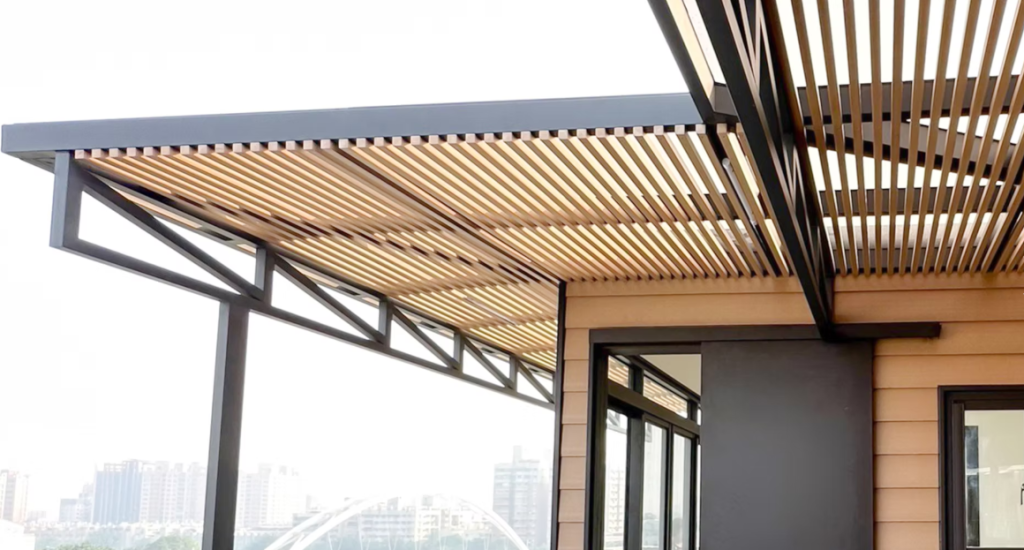

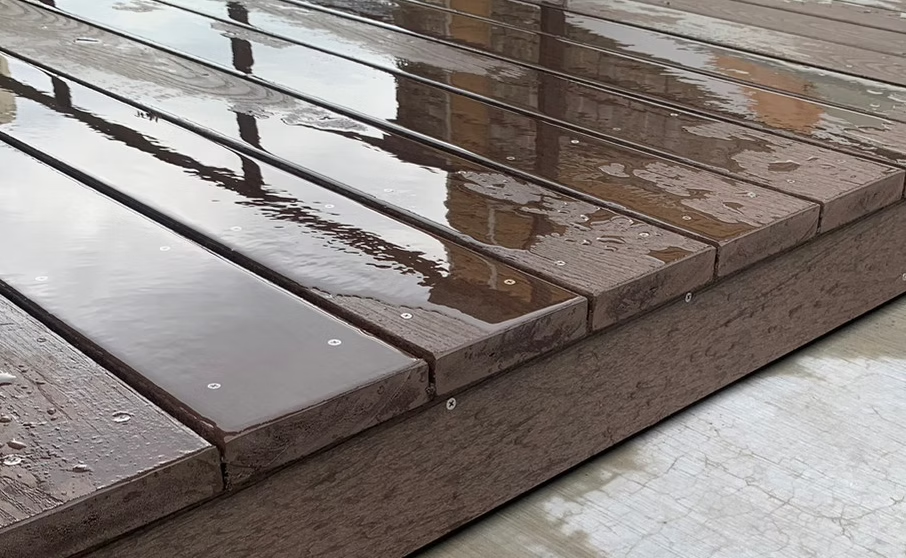

GREENuWood waste can be recycled and reused

The remaining materials from the cutting of GREENuWood and the replacement materials after use can be recycled and reused, implementing the circular economy. Planting trees in the factory does not consume any forest resources.

Product carbon footprint

The data speaks for itself. The ISO14067 carbon footprint has been completed and verified by a third party, so the specific carbon emissions are clear at a glance.

The old plastic is reborn

Quality

GREENuWood has passed the national plastic wood standard CNS15730, SGS certification, and the green building material label.